News

Food Sector is the Largest Downstream Application Market for Global Square Bottom Valve Bag Making Machines

Date:

2025-2-11

Food Sector is the Largest Downstream Application Market for Global Square Bottom Valve Bag Making Machines

Square bottom valve bag making machines are automated equipment used to produce square bottom valve bags. Square bottom valve bags are a commonly used type of packaging bag with a flat, self-standing base, making them convenient for filling. These machines can automatically complete processes such as bag forming, sealing, and cutting, significantly improving production efficiency and product quality. Typically composed of feeding mechanisms, bag-forming units, sealing units, cutting units, and control systems, the equipment can be customized and adjusted according to different production needs. Square bottom valve bag making machines are widely used in industries such as food, chemicals, pharmaceuticals, and agriculture, making them efficient, stable, and reliable packaging solutions.

Introduction to the Square Bottom Valve Bag Making Machine Industry Chain

Equipment Manufacturing: The production of square bottom valve bag making machines is the core of the entire industry chain, requiring advanced manufacturing technologies and equipment such as CNC machining tools, welding systems, and painting facilities.

Component Supply: These machines rely on a large number of components, including motors, cylinders, sensors, and controllers. These parts must meet high standards of quality, reliability, and durability to ensure machine stability and performance.

Software Development: Specialized software, such as PLC control systems and touchscreen interfaces, is essential for operating and managing the machines. Software development is tailored to the equipment's features and production requirements.

After-Sales Service: After-sales support is a critical part of the industry chain, encompassing installation, debugging, maintenance, and technical training to ensure smooth operation and optimal productivity.

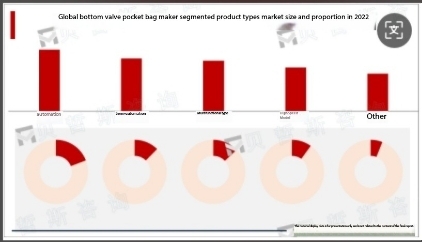

Overview of Mainstream Square Bottom Valve Bag Making Machines

Fully Automated Square Bottom Valve Bag Making Machine: A fully automated solution capable of independently performing bag forming, sealing, and cutting, ideal for large-scale production.

Semi-Automated Square Bottom Valve Bag Making Machine: Requires manual intervention for tasks such as material loading and bag length adjustment, suitable for small and medium-scale production.

Multi-Functional Square Bottom Valve Bag Making Machine: Designed to produce valve bags in various sizes and materials, catering to diverse production needs.

High-Speed Square Bottom Valve Bag Making Machine: Optimized for rapid production, enabling high-volume output for large-scale and high-efficiency operations.

In summary, mainstream square bottom valve bag making machines offer distinct features and applications, allowing businesses to select or customize models based on their production requirements.

Market Overview of Square Bottom Valve Bag Making Machines

Application Fields: These machines are widely used in food, chemicals, pharmaceuticals, and agriculture, with the food industry being the largest market segment.

Regional Distribution: The market is primarily concentrated in Asia-Pacific, Europe, and North America, with Asia-Pacific being the dominant region.

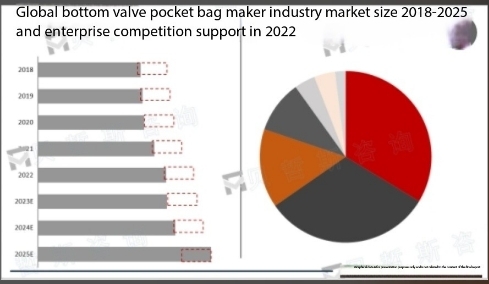

Market Size: Driven by packaging industry demand, the market for square bottom valve bag making machines continues to expand and is projected to reach approximately $3.1 billion by 2025.

Competitive Landscape: The market is highly competitive, with key players including Germany’s Windmöller & Hölscher, Italy’s Gavi, and China’s Shanghai Baode.

Technological Trends: Ongoing advancements are enhancing production efficiency and product quality, while innovative machine types such as multi-functional and high-speed models are emerging.